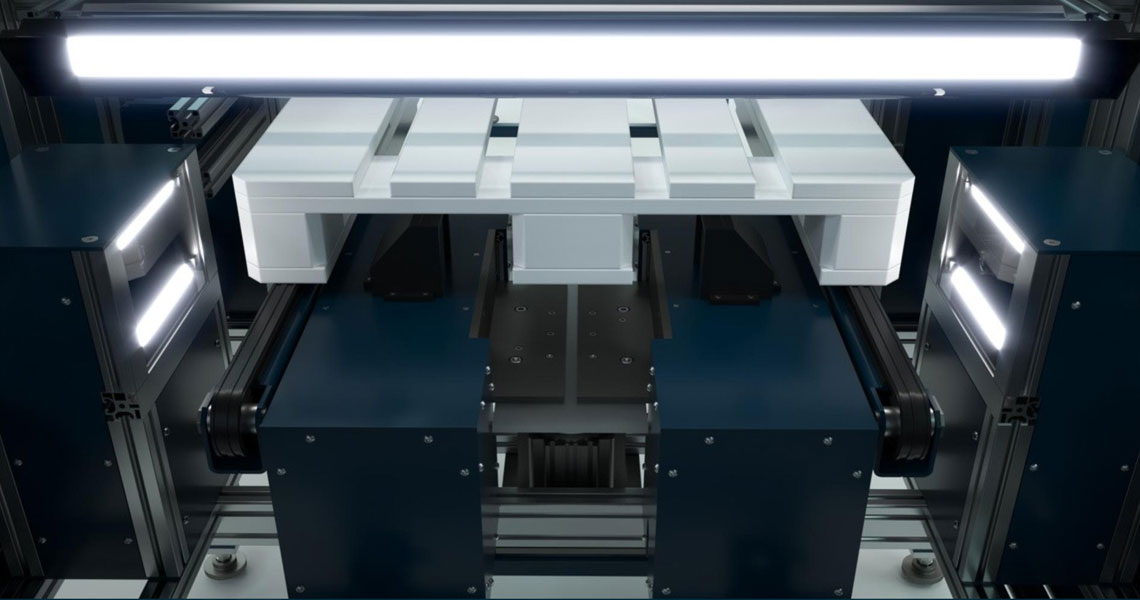

Our pallet inspection solution, the PALLETAI, provides real-time monitoring and control with precise data logging and analysis. Yes, we know, it is as sexy as it sounds. Just imagine all the cameras, LEDs, and lasers working in perfect symbiosis, ready to solve the problem of inconsistency in the quality of pallets.

Machine Vision is about combining and using cameras, sensor technologies, lights, lasers, and optics with well-thought-out geometrical alignments. This, together with our great mathematical capacities and our knowledge and passion for staying up to date with the latest standards, enables vivid conceptualization and great design. In addition, we apply lateral and vertical thinking, which allows us to think outside the box and develop brilliant designs that provide us with important patterns based on known information.

Still not convinced? Then just imagine that the IVISYS team embraces brilliant knowledge in all important areas of machine vision that will solve the utmost challenges and ensure the quality of both wooden and plastic pallets. If you are eager to know more, read the benefit summary in bullet form that will surely impress you.

Machine Vision explained for busy people

What’s all the fuss about, in essence? Our solutions to pallet inspection, the PALLETAI are impressive but reading long texts can be tedious, we know. So, for the busy, here is the list of why it’s worth getting to know more of the area of machine vision.

- Non-contact measurement by using machine vision hardware components such as cameras, LEDs and lasers.

- Unique and patented software solutions.

- Real time control and monitoring.

- Precise data logging and data analysis.

Vision explained, for the interested.

More stuff to read here if you want to hack your success.

So, you’re tech-savvy and inquisitive? You want to know how machine vision works in detail?

We identify and apply the machine vision hardware out of the task it’s supposed to perform and the specific production or logistics application where it’s going to be used. Cameras can be set for different resolutions and monochromatic or color, and the illumination can be LED-lights or lasers in different wavelengths. The camera lenses are chosen based on the specific geometry and the field of view needed for the task.

Light is made of elementary particles, called photons, which rides on the electromagnetic field as radiation. Depending on the thermal properties of the particle, it vibrates at different vibration speeds, which, when carried by the electromagnetic field, become a wave. The wave leads to radiation of different wavelength spectrums like the UV-spectrum, visible spectrum, infrared spectrum, and so on.

When the photon hits an object, the object reflects some wavelengths and absorbs other wavelengths leading the reflected photons beams out in various directions, or in controlled directions, depending on the object material/surface, its geometry and what illumination technology was used.

The photons of the reflected wavelengths are gathered by a lens in different ways, depending on its construction. Lenses are chosen based on which electromagnetic spectrum we’re looking to detect, how much of the object that needs to be seen, at what distance the object is from the image acquisition device (i.e., camera) and what light reflection geometry needs to be detected.

When the light passes the lens, it is gathered by the image acquisition device, the sensor, in so-called “photon wells” where the photon’s energy is “transformed” into electrons that in turn are converted to a voltage level. This voltage level can be digitized to a value, a digital number – a DN, a value depending on the sensor’s bit depth.

These DNs are then structured into a matrix to form an image of the true world object that allows different kinds of measurements and analysis to be applied.

Crystal clear, isn’t it?

If you have any questions you can always reach out to our Machine Vision Wizards at info@ivisys.com or if you happens to be in the US or Canada info@ivisys.us.