Improved quality and efficiency

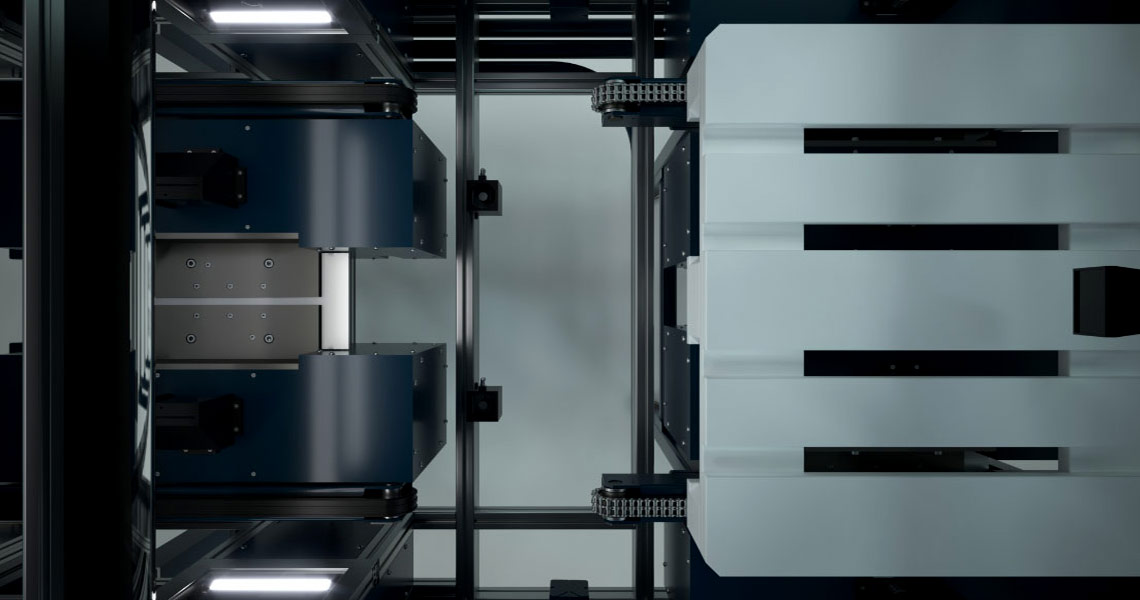

With the growing need for automation and automated processes, pallet quality plays a crucial role in securing the productivity and uptime of these automated systems – regardless if it’s pallet conveyance, automated storage and retrieval systems or palletizing. Therefore, having pallets of correct quality for your operation is crucial in enabling automation with a high and stable productivity and warehouse flow.

By understanding the value of quality pallets, you can optimize the logistics and warehouse strategies to improve your operations. IVISYS PALLETAI offer you solutions for both empty and loaded pallets, wood, and plastic pallets, tailoring the level of acceptance and reject criteria to your specific needs so you can handle the logistics challenges the most efficient way. IVISYS PALLETAI helps you improve your logistics and warehouse efficiency regardless of pallet type; wooden, plastics, EPAL, CHEP,GMA, PEC, LPR, iGPS or other sorts of pallets.

Why settle for defective pallets?

IVISYS PALLETAI ensures that pallets entering the operation are suitable to use. If you sort pallets inhouse or outsourced, it also saves manual sorting costs while improving the quality of pallets. IVISYS PALLETAI is a scalable solution, and the PALLETAI can accept more pallet types (even with different sizes) added over time to meet changing demands. The PALLETAI can be implemented in your existing warehouse and logistics chain or designed as a complete stand-alone-solution for your improved automated warehouse.

An attractive ROI

At around 50 000 or more empty or loaded pallets annually, there’s a strong likelihood that the PALLETAI will return an attractive ROI for any business in the Food and Beverage Industry. IVISYS deliver robust solutions, which do not require any change over time between different pallet types and recipes. With minimal daily maintenance requirements, more time can be spent on focusing on value added activities. IVISYS offers remote performance monitoring, ensuring that your operation is running as intended and which enables preventative maintenance in case of early warnings. The annual maintenance contract which gives peace of mind securing that any wearables (regardless of inspection system, conveyor/material handling equipment) are replaced, camera equipment is calibrated, and firmware is updated on a selected maintenance schedule.

At one Customer in Food and Beverage, at least once a week a pallet gets stuck in their palletizing cells or disrupts the automated warehouse. With one out of seven cranes taken out of service for an average of one hour to two hours with worst cases stretching upwards of twenty-four hours the warehouse efficiency is highly impacted. Operational 6 days per week over three shifts, this gives around 45000 operational hours, which yields a per hour value of SEK61000 per crane. With 50 events per year, the total cost ends up being ~3,1MSEK. This could easily be reduced by assuring the quality of the pallets by inspecting pallets with IVISYS PALLETAI.

Designed for safety

IVISYS PALLETAI can detect nail protrusions all around a pallet and with any form of manual handling of the pallet, you can be sure that your staff is not getting injured due to protruding nails or other hazardous defects. It is a well-known fact that defective pallets can break when being handled with goods on, which increases the risk of staff becoming injured from the pallet or goods on the pallet falling on them. IVISYS PALLETAI also helps to improve warehouse automation and the HSE benefits.

Sustainable pallet handling and flow

Decreased footprint impact of your end-to-end system compared to traditional mechanic and manual sorting systems. IVISYS PALLETAI contributes to a smaller footprint of the end-to-end system compared to traditional mechanical and manual sorting system. IVISYS PALLETAI solution drives reduction in emissions through your pallet supply chain by accepting unsorted pooled pallets, removing the need for them to go through a depot for sorting which incurs additional transportation emissions.

One of IVISYS customers in the Food and Beverage Industry is shipping 3 000 000 pallets per Year. To be able to handle such volumes of pallet inspection; it would require around 3600 full truck loads at 50 km roundtrip. Avoiding these shipments alone would save 1 280 000 kg of CO2 emissions annually. With 3 000 000 pallets per Year, if 15 percent of 390 000 pallets are defective, the customer must pay 30 SEK per pallet, the total cost of sorting and repairing pallets would be 11,7 MSEK per Year. If you calculate the direct costs, plus indirect costs for on/off loading pallets the value of loading time would end up allowing you to excessive savings. By integrating IVISYS PALLETAI great amount of savings from various aspects undoubtedly could be achieved, and the ROI increased significantly compared to off-site sortation.